1.Introduction

geokon Model 4000 vibrating wire strain gauges are intended primarily for measuring strain on structural steel members such as tunnel linings, arches, struts, piles, sheet piling, etc. They may also be used to monitor strain changes on concrete or rock surfaces. Attachment to steel surfaces is accomplished by arc welding the mounting blocks to the surface; other surfaces require special mounting blocks with rebar anchors that are grouted into boreholes.

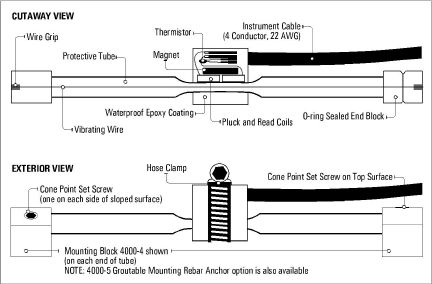

Strain is measured using the vibrating wire principle. A length of steel wire is tensioned between two mounting blocks that are welded to the steel surface being studied. Deformations of the surface will cause the two mounting blocks to move in relation to each other, altering the tension in the steel wire. This change in tension is measure□d as a change in the resonant frequency of vibration of the wire.

Figure 1: Model 4000 Vibrating Wire Strain Gauge

Two coils, one with a magnet insert, the other with a pole piece insert, are located close to the vibrating wire. In use, a pulse of varying frequency (swept frequency) is applied to the coils causing the wire to vibrate primarily at its resonant frequency.

Portable readouts and dataloggers are available from geokon. These models, when used in conjunction with vibrating wire strain gauges, will provide the necessary voltage pulses to pluck the wire. During vibration, a sinusoidal signal is induced in the coils and transmitted to the readout box where it is conditioned and displayed.

This manual contains installation instructions, readout instructions, recommended maintenance, and troubleshooting procedures. The theory of the gauge is also given, along with some suggestions for data interpretation.