Appendix D.No Stress Strain Enclosure

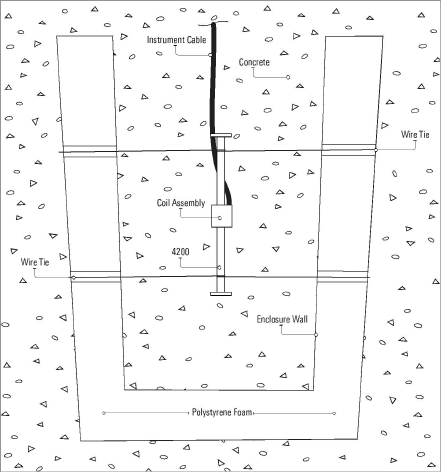

geokon's Model 4200-4 No Stress Strain Enclosure is a double walled PVC cylinder with the wall cavity filled with polystyrene foam. The figure below shows a standard 4200-4 installation.

19:

Figure 19: No Stress Strain Enclosure

The purpose of the no stress enclosure is to position a strain gauge so that it is not subject to changes in strain in the mass concrete surrounding it, yet still remains subject to changes in strain caused by the fluctuation of moisture content, temperature, and alkali/aggregate reaction. The data gleaned from the No Stress Strain Gauge can be used to apply corrections for these phenomena to the other strain gauges in the mass concrete, allowing the user to quantify only those strains that result from stress changes.

Installing the 4200-4 Enclosure

1.Position the enclosure inside the concrete mass with the top open so that it can be easily filled with concrete. (Often the 4200-4 will be placed next to a strain gauge rosette.)

2.Mount the strain gauge by wrapping two turns of tie wire around the gauge and then feeding the ends of the wire through the holes in the opposite sides of the enclosure.

3.Wrap the ends of the tie wire around the outside of the enclosure and tie together.

4.Use a tie wire tightening tool or similar device to tighten the wire.

5.Repeat this procedure, using another tie wire and the second set of holes in the enclosure.

6.Arrange the instrument cable so that it exits through the top of the enclosure.

7.When pouring concrete into the enclosure, remove aggregate that is too large. Be careful not to disturb the gauges during the filling process.