Loading... Please wait...

Loading... Please wait...- GEOKON (S) PTE. LTD.

- GEOKON Latin America

- GEOKON Canada

- GEOKON OpenAPI

- Site Map

- +1.603.448.1562

- Subscribe

Projects

Dams

-

Overview

GEOKON instruments have been used to monitor and analyze critical elements of numerous dams throughout the world. Dams of any kind can benefit from instrumentation — including concrete, rollcrete, RCC and earth. GEOKON instruments are used in the dams of USA, China, Spain, South Africa, Brazil, Czech Republic, Switzerland, Colombia, New Zealand, Kenya, Pakistan, Algeria, Indonesia, Thailand, Vietnam and Australia.

Learn more about our dam monitoring, data collection and long-term reliability…

Case Histories

-

Asahan III Hydroelectric Power Plant

North Sumatra, Indonesia

One of the major components of the Asahan III Hydroelectric Power Plant project in North Sumatra, Indonesia is the construction of an underground powerhouse to house two 87 MW turbines. HMA Group, an authorized GEOKON system integrator, was contracted to supply instrumentation for the powerhouse, and to design a datalogging system capable of reading the instrumentation remotely. An essential part of this system is a large quantity of modified GEOKON Model 8020-30 Addressable Vibrating Wire Interfaces, which will essentially act as terminal boxes for much of the geotechnical instrumentation, including several GEOKON piezometers and load cells.

Project submitted courtesy of Alex Hyland and Muhammad Iqbal of HMA Group.

-

Ban Ve Hydropower

Tuong Duong District, Nghe An Province, Vietnam

Instrumentation used: Model GK-604D Digital Inclinometer System

Project submitted courtesy of Vietnam Environmental and Geotechnical Instrumentation Joint Stock Company (VEGI JSC), Vietnam.

-

Cua Dat Hydropower

Thuong Xuan District, Thanh Hoa Province, Vietnam

Instrumentation used: Model 4420 Crackmeter

Project submitted courtesy of Vietnam Environmental and Geotechnical Instrumentation Joint Stock Company (VEGI JSC), Vietnam.

-

Khe Thoi Hydropower

Con Cuong District, Nghe An Province, Vietnam

Instrumentation used: Model 4500S Standard Piezometers

Project submitted courtesy of Vietnam Environmental and Geotechnical Instrumentation Joint Stock Company (VEGI JSC), Vietnam.

-

Quan Tri Hydropower

Huong Hoa District, Quang Tri Province, Vietnam

Instrumentation used: Model 4911 Rebar Strainmeters | Model GK-404 Handheld Vibrating Wire Readout

Project submitted courtesy of Vietnam Environmental and Geotechnical Instrumentation Joint Stock Company (VEGI JSC), Vietnam.

-

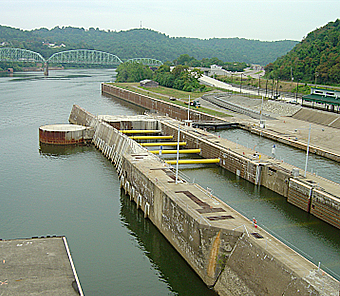

Lower Mon Project

Pennsylvania, USA

The Lower Mon Project was initiated by the US Army Corps of Engineers to keep river transport economical through the lower part of the Monongahela River. The project consisted of replacement of the 100 year old fixed-crest dam near Braddock (Locks and Dam 2) with a gated dam (completed in 2002), construction of two new larger locks at the Locks and Dam near Charleroi (Locks and Dam 4) and removal of the Locks and Dam near Elizabethtown (Locks and Dam 3). Maintaining stability of the existing lock walls was a critical requirement for all this construction activity so instrumentation and monitoring was specified by the Corps to provide this information.

Instrumentation consisted of 17 GEOKON Model 6300 Vibrating Wire In-Place Inclinometers each consisting of 6 or 7 sensors installed in the river and middle walls, to a depth of 105' (32m), as well as piezometers to provide pore pressure and water level information inside and outside the cofferdam. Four Canary Systems MLDAQ monitoring systems placed approximately in the corners of the cofferdam were required to optimize cabling and connections to the instruments, each including a solar power system, wireless communications, Canary Systems VWDSP Interface for high reliability gage readings, lighting protection through Canary Systems MultiMux multiplexers with integrated OVP components on each channel, as well as high-powered 144 dB sirens and strobes to provide audible and visual alerts for construction personnel.

Distribution of data was accomplished by use of Canary Systems MultiLogger Suite software platform. The USACE had remote access to the on-site PC for retrieval of data and chart and report creation. The on-site monitoring PC also provided voice message phone alarm through use of a digital I/O card and voice dialer controlled by Insite, the client data access software of MultiLogger Suite.

For additional information, please view the Canary Systems Project Profile

-

Bluestone Dam

Hinton, West Virginia, USA

Bluestone Dam, in Hinton, West Virginia, was built between 1941 and 1949 to control flooding in the New and Kanawha River Valleys. It’s constructed of a series of 55 x 165 ft high, 22 ft wide (at base) interlocked concrete monoliths. Recent calculations identified the possibility for dam failure due to the monoliths sliding on the bedrock.

As a result, a total of 216 high-strength anchors, comprising of 58 to 61/0.6 high strength multi strands, were installed at critical monoliths to stabilize the dam. This photo, kindly shared by DSI America, shows a GEOKON Model 4900-3500-12 Vibrating Wire Load Cell mounted on the 15,000 kN hydraulic ram (20" stroke) used to stress the anchors.

-

Xiluodu Hydropower Plant

Sichuan Province, China

China’s 13,860 MW Xiluodu hydropower plant was recently connected into the country’s power grid. Located on the Jinsha River in central Sichuan Province, Xiluodu will be the world’s third-largest hydropower plant, after China’s Three Gorges and Brazil’s Itaipu, when it is fully completed in 2015. Work on the dam started in 2003, and since 2005 GEOKON has shipped more than 140 orders for the dam monitoring instrumentation required in the project. Instruments included Extensometers, Vibrating Wire Strain Gages, Vibrating Wire Piezometers, Vibrating Wire Displacement Transducers, Vibrating Wire Load Cells and Vibrating Wire Concrete Stressmeters.

For additional information, please contact: Mr. Shen | Geokon Instruments (Beijing) Co., Ltd

-

Tsankov Kamak Dam

Southwestern Bulgaria

In early 2008, GEOKON's Canadian division, GKM Consultants, was awarded a major contract to provide the instrumentation system for the Tsankov Kamak Dam in Bulgaria. Tsankov Kamak Dam and Hydroelectric Power Plant, located near the town of Devin, is a concrete arch dam, with double curvature and a height of 130.5 m. Its length at crest is 468 m, volume content is 465,000 m³ and reservoir cross capacity is 110,900,000 m³.

In co-operation with Petko Slavov, GEOKON's Bulgarian Representative, GKM Consultants provided instruments to measure seepage, stress, displacement, temperature, foundation pressure, seismic acceleration, weather parameters and more. In addition, a complete automatic monitoring system was deployed inside the dam through a fiber optic communications network.

GEOKON/GKM Consultants also provided Vista Data Vision (VDV) data visualization software to facilitate management of all data gathered. The VDV system displays data as graphs and tables through a special mimic board, which makes it much easier for site Engineers and Operators to monitor the dam’s behavior. The same information is also accessible anywhere, via the Internet, using the VDV web browser module.

For additional information, please contact: Stéphane-Éric Thivierge, ing. | GKM Consultants

Petko Slavov | Bulgaria

-

Hiwassee Dam and Power Plant

North Carolina, USA

The Hiwassee Dam and Power Plant on the Hiwassee River near Murphy, North Carolina, was built by TVA between 1936 to 1940 as a flood control and electrical generating facility.

Concrete growth at Hiwassee Dam, caused by an alkali-aggregate reaction (AAR) has caused expansion of the dam, partially closing the spillway, jamming the gates and causing significant structural cracking in the abutments.

Over the years various types of remedial action have been undertaken, including the cutting of slots and the installation of post tensioned anchors on the spillway piers. At present there are approximately 325 instruments connected to six automated systems monitoring the dam and the efficacy of the remediation.

A database (MultiLoggerDB from Canary Systems, Inc.), to manage the instrumentation data was deployed in 2004 and has been in continuous operation since.

For additional information regarding data acquisition, please contact: Alex Neuwirt | Canary Systems, Inc.

-

Barrios De Luna Dam

Barrios De Luna, Leon, Spain

At the Barrios De Luna Dam, Piezometers installed in the foundation are being used to monitor uplift pressures while Crackmeters, installed between concrete blocks (15 m below the crest), measure any opening or closing of the joints between the same.

For additional information, please contact:

Javier Andreu | Ingeneria de Instrumentacion Y Control

-

Baishan Dam

Northeast China

Baishan Dam is a 149.5 m high gravity arch dam on the 2nd Songhua River. It is one of the largest dams in the northeast of China. The dam is 677.5 m in length and was constructed using 1,663 km³ of concrete. It impounds a 6,500,000,000 m³ reservoir and has the capability to control a 19,100 m³/s flood from a 19,000 km³ catchment. Over 100 vibrating wire instruments, including vibrating wire Piezometers to monitor uplift pressures, and vibrating wire Tiltmeters to monitor deflections, have been installed in this dam.

For additional information, please contact: Jiang Xiaogang | Geokon Beijing Co.

Share your Project!

GEOKON would like to share customer projects and success stories with the visitors of our website. If you would like your project summary to be featured on our Recent Projects page, added to our collection of various Projects and promoted on social media, please complete and submit your project for review and consideration. As a token of our appreciation, GEOKON will send you a small gift for your contribution!